Rotating Table

This was a project I worked on summer 2017, during my internship with mHUB Chicago. My boss, director of operations at mHUB, asked if the interns could design a simple table to commemorate our time there. He showed me some pre-made plans on the internet; I just had to download the files and use a CNC milling machine to cut the pieces for assembly. Instead, I thought, Why do I have to build someone else's table? Then I kept thinking, What would make a table cool? Some of my fellow interns and I brainstormed for a while, and we came up with this:

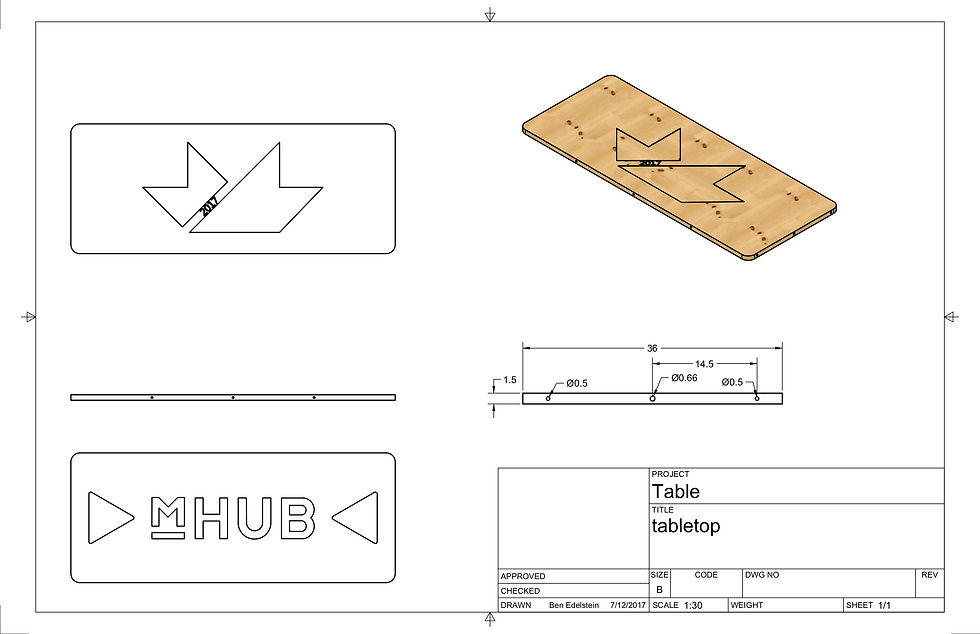

We designed a double-sided, dual-purpose table that rotates on a central shaft attached to ball bearings. The tabletop is locked into place using dowel rods and side rails, which are easily removable. I led the project and designed the CAD/CAM on Autodesk Fusion 360. The wood was cut using ShopBot CNC. Check out the design process, and let me know what you think! (All pictures mine)

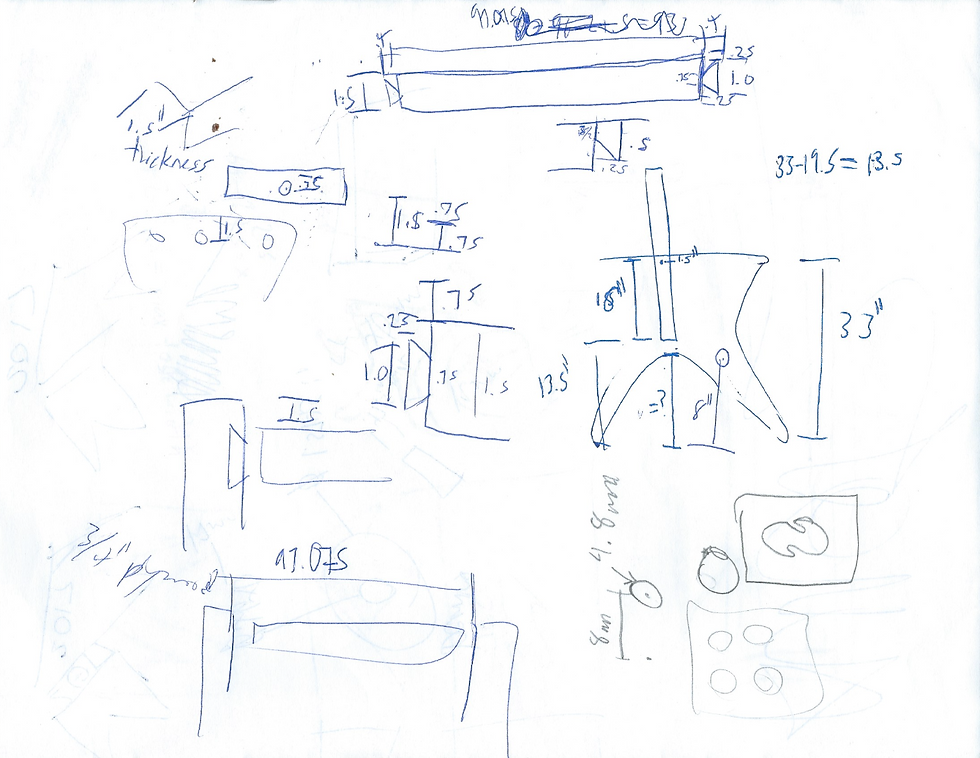

Sketching

I spent a good deal of time figuring out how the rotation mechanism would work, and how to support the table if it couldn't be supported from the middle (due to the rotational constraint). I also needed to consider designing for manufacturability, something that I had never dealt with before, especially in terms of wood fabrication. Before this, I hadn't used much more than a simple bandsaw.

Final Design

Here are some CAD renderings for the final prototype, designed in Autodesk Fusion 360. Fusion also has a built-in CAM path tool, which we used to create the CAM files for CNC milling. Check out the photos, and let me know what you think! Don't hesitate to contact me with any questions, comments, or suggestions.